Taking a look from the PPE perspective

Published by David Bizley,

Editor

Oilfield Technology,

Lee Taylor, Wenaas, UK, explores the importance of specially designed PPE and work wear for the increasingly extreme environments faced by the oil and gas industry.

Attitudes towards offshore health and safety have come a long way in recent years. Heightened regulatory processes along with major advances in technology have meant that offshore workers are now better equipped to deal with the increasing demands of their roles in harsher climatic environments than ever before.

Health and safety has become a huge industry in its own right, with oil and gas industry bodies funding a multitude of research and development projects to provide the latest safety resources for their workforce. Included in this is the personal protective equipment and work wear sector, which has progressed in tandem with other strands of health and safety. As the offshore workforce evolves, so does the requirement for updated PPE and work wear. This is perfectly illustrated by the recent research undertaken by a university based in Aberdeen, which has assessed the implications of a physically growing offshore workforce upon a number of health and safety measures in general – not least the efficacy of PPE and work wear. The question is – have the work force’s habits changed sufficiently to ensure the right procedures are being followed?

Wenaas is a designer and manufacturer of work wear and PPE, and understands the importance of investment in research and development to continually optimise and improve work wear and PPE. It is on the basis of this commitment to R&D - and a ‘head-to-toe safety’ ethos - that Wenaas has been involved in research projects which aim to develop superior protection work wear, fit to cope with the extreme demands that the petroleum industry supplies.

Wenaas Arctic range.

This is important, because whilst the North Sea offshore industry holds a relatively positive track record for safety, E&P activity is moving into more hazardous, remote and ultimately more dangerous areas, as the search for reserves continues. This presents increasingly challenging environments within which work wear and PPE must perform, whilst highlighting the need for the emergence of innovative solutions and education on how to use those solutions to their best advantage.

Arctic protection development

The oil and gas industry has been advised by the Barents 2020 project to adopt work clothing and PPE specific to the environmental conditions of the Arctic in order to secure workers’ health, performance and safety in extreme meteorological conditions.

The Petromaks Project

Wenaas has been called upon as a partner in current research for the development of a new range of work wear and PPE for extreme cold climates. The groundbreaking project – known as Arctic Protection – is part of an overarching research project called Petromaks, involving a number of companies who are researching different areas in the oil and gas industry. The Arctic Protection project reflects the recommendations of Barents 2020, and originates from collaboration between Wenaas parent company Kwintet Norge, research-based innovations company SINTEF, Statoil and Eni Norge.

The project builds upon existing knowledge from the Scandinavian ColdWear research project, which investigated how the interaction between environmental exposure, clothing, workload, and physiological regulatory system affect working conditions. It concluded that existing work wear does not meet the requirements to maintain acceptable dexterity in cold temperatures. The health and safety implications of a loss of easy movement are manifold in the offshore environment.

A main issue research has identified with current products is a distinct lack of manual dexterity and grip strength, when wearing standard work wear gloves. Thus workers are removing gloves to execute tasks, which at sub-zero temperatures, is not only unsafe but also reduces manual performance. Other areas highlighted through operator feedback include the need for work coveralls with proper storage for common tools used in the Arctic, and thermal protection to keep wearers warm built into clothing that is light and allows proper movement. Restriction due to inefficient layering has been noted as a key issue in extreme cold. To ensure total protection of workers, this research has identified that the compatibility of PPE and work wear is essential for simultaneous use in a safe, practical way.

Work wear examined in this Arctic project has included personal protective clothing and products for the thermal protection of the head and hands via new design hats and gloves as well as Arctic footwear. The level of innovation in the project will mean there are now beneficial implications for workers in other industries too, such as mining and the marine sector.

Having begun in January 2014, Petromaks is expected to run for three years, reaching completion in the early months of 2017. The research and development phase of the Arctic Protection project is broken in to five key stages. Research has already been conducted to establish the work wear user needs, which has lead to the development of new solutions. These solutions are now being built in to prototypes for evaluation and identification of critical problem areas. The final step will involve a plan for the industrialisation of the new work wear, namely a quality assured way of up-scaling work wear production.

These early prototypes have already been developed by Wenaas, based on specifications of the selected solutions from the concept development phase. Adjustments were made during the developmental phase in order to accomplish early evaluation of how the solutions would work in their intended work situation in the cold when put to the test by Statoil employees.

The first prototypes were tested late 2014 on a platform operated by Eni Norge, and will be followed by more extensive tests on a platform further north over the next few months.

The results of the project will contribute to increased safety and work efficiency in outdoor work situations in the Arctic, but will undoubtedly also contribute to the future of North Sea winter protection. The solutions from this research and development will significantly improve protection in Arctic and winter conditions on the basis of thermal protection and regulation, manual performance, functionality and comfort and total protection. Increased thermal protection and temperature regulation will enhance work comfort, whilst preventing the effects of cold related injuries and accidents. The ultimate result will be a safer, more productive - and therefore more cost-effective - workforce. In other words, the key objectives of any company operating within the oil and gas sector.

Vital layering – whatever the temperature

Safety in a hazardous offshore environment does not just stop at the external protection - optimum levels of safety are achieved by correct layering, too. Research in this area has led to the identification of key procedures for dressing in extreme temperatures, whether they be hot or cold. Selecting the appropriate base and mid layers for the environment, activity and temperature is crucial in either situation, and Wenaas has worked closely with undergarment provider, Devold® Protection, to uncover evidence that undergarments which maintain a core body temperature against extremes will significantly contribute towards total protection.

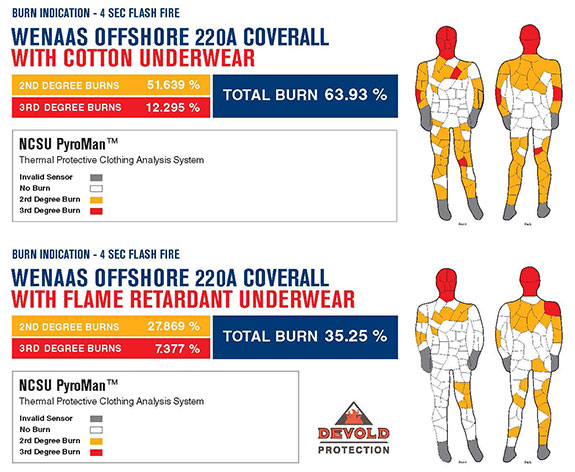

PyroMan™ burns test results.

The benefits of a stable core body temperature in Arctic conditions are fairly obvious. However, the importance of layering to maintain a core body temperature in less extreme working environments is often forgotten. It is highly likely that synthetic items (such as many sports tops) could be worn underneath a coverall – and that will do little to maintain a stable core body temperature or prevent moisture build up, should the wearer become exposed to the dangers of fire. It is recommended that in addition to outerwear, the oil and gas industry should provide undergarments to employees, which only use Tasmanian Merino wool. Unlike synthetic fibres, Merino wool significantly reduces the risk of scalding as the wool’s wicking properties effectively trap the moisture that builds up with synthetic undergarments, which would otherwise remain on the skin and boil, causing serious damage.

By commissioning PyroMan™ tests at North Carolina State University, the significant difference that correct layering can make to employee safety, during exposure to flame was illustrated. The simulated flash fire exposure used sensor-covered mannequins, dressed in our Offshore fire retardant coverall, to measure heat transfer, predicting the likelihood of 2nd and 3rd degree burns between those wearing standard cotton undergarments and those layered with the merino wool undergarment.

The results showed that this layering combination reduced the extent of 2nd and 3rd degree burns by 30%. This is an exceptional result considering a 50% 3rd degree burn means a high risk of loss of life - particularly important when taking older employees into account, as recovery rate from 50%+ burns reduces significantly with age. It’s even more significant, when you consider that those offshore are likely to be wearing not cotton, but synthetic undergarments, which of course produce even more moisture.

Results such as these must surely convince the oil and gas industry that attention must be paid to what is being worn underneath the statutory outer garments and that offshore garment layering attitudes and habits need to change.

By commissioning those independent tests, we illustrated the vital difference to safety that correct layering can make. It is so important that an increased emphasis is placed upon correct garment layering for offshore personnel and the need for contractors and operators to consider provision of appropriate undergarments as well as coveralls in protecting their workforce – it is literally a matter of saving lives.

We know our PPE and work wear works effectively, saving time, money and lives, but to ensure this is the case across the entire oil and gas industry, moves must be made to ensure that clothing and PPE standards are not only in place, but are constantly implemented by those on the ground.

Encouraging the safety culture

Whilst PPE and work wear can be improved, it is only really effective when actually used – and used correctly. Whilst an employer can kit its workforce out, it will often encounter problems encouraging PPE/work wear best practice. Wenaas has come up with a solution to this.

It has created KWS, a new ordering system that can give staff a pre-determined degree of control over their own PPE and workwear choices. Adaptable to different countries, roles and user types, the secure system allows employees to order relevant items for themselves, thus giving them an element of control and ownership of their own items. The opportunity to add text, logos and adjustments to the order reinforces that idea of ‘bespoke’ PPE and workwear, which in turn encourages responsible use. Furthermore, the system can ‘embed’ in the company culture, being customised to reflect company brand and include in-house information on the home page, such as uniform and safety rules.

By creating a very visual catalogue, available 24/7, 365 across all digital platforms, the purchasing process is simplified and decentralised, providing time and cost savings as well as clear budgetary control and traceability of each transaction from order to delivery to invoicing.

This ordering process has advantages for both employer and staff, and helps ensure that the oil and gas industry understands the supreme importance of effective PPE and workwear and continues to do all it can to promote best practice in this field.

Adapted by David Bizley

Read the article online at: https://www.oilfieldtechnology.com/special-reports/13052015/taking-a-look-from-the-ppe-perspective/

You might also like

TotalEnergies increases its interest in giant field Moho and divests two mature assets

TotalEnergies announces that its 85%-owned affiliate, TotalEnergies EP Congo, has signed an agreement with Trident Energy combining the acquisition of an additional 10% interest in the Moho license from Trident Energy and the sale to Trident Energy of its 53.5% interest in the Nkossa and Nsoko II licenses.