Shand & Jurs improves Tank Blanketing Valve

Published by Callum O'Reilly,

Senior Editor

Oilfield Technology,

Shand & Jurs has announced improvements to its 94270 Tank Blanketing Valve.

The 94270 Tank Blanketing Valve now incorporates a new internal Teflon® O-ring coating which improves the performance of the unit and reduces maintenance time and costs.

This new Teflon® coating is now part of Shand & Jurs’ standard offering for its 0.5 in., 1 in. and 2 in. tank blanketing valves. The 94270 is also available with accessories including filters, check valves and pressure gauges.

'Tank blanketing' is a process used to maintain a gas barrier in the vapour space of a pressure-tight storage tank. It prevents evaporation, reduces emissions, corrosion, contamination or oxidation and provides gas make-up when internal tank pressure drops. The S&J 94270 Tank Blanketing Valve provides primary vacuum relief by controlling the flow of blanketing gas into the tank during product movement out of the tank.

Adapted from press release by Callum O'Reilly

Read the article online at: https://www.oilfieldtechnology.com/product-news/28042014/shand_and_jurs_improves_tank_blanketing_valves_037/

You might also like

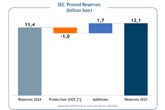

Petrobras increases Proved Reserves in 2025

Petrobras discloses its proved reserves of oil, condensate and natural gas, according to SEC (US Securities and Exchange Commission) regulation, estimated at 12.1 billion boe, as of December 31, 2025.