Qualitative risk-based inspection – keeping it simple

Published by Nicholas Woodroof,

Editor

Oilfield Technology,

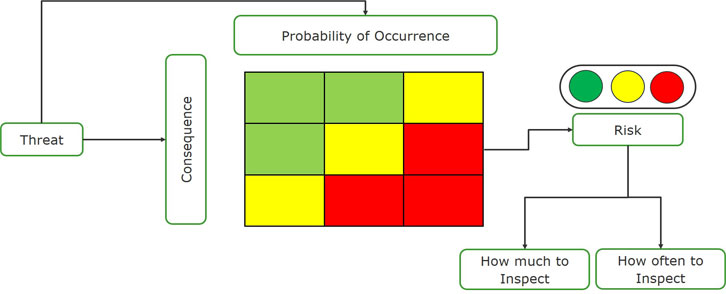

Most, if not all, of the offshore structures in the UKCS use a risk-based inspection (RBI) methodology for subsea and topsides inspection planning. With an ever-increasing focus on reducing the cost of maintenance and the need to ensure topside equipment functions reliably and sustainably, operators need to ensure the frequency of inspections is correctly focused (Figure 1).

Figure 1. Risk-based inspection is the process of developing a scheme of inspection based on knowledge of the risk of failure.

With a vast array of topside structures to inspect, clarifying and reporting on the likelihood of failure and the potential consequences, is a mammoth task. Analysing fatigue in a jacket or hull structure, for example, uses a quantitative approach where a range of data is fed into a system to compute and evaluate the risk. For topside structures, there is a lack of good quantitative systems or data, with some only focused on particular failure mechanisms. While there are ‘semi-quantitative’ approaches, it is widely acknowledged that combining data and experience can create confusion and thereby, lead to falsehoods and misinterpretation.

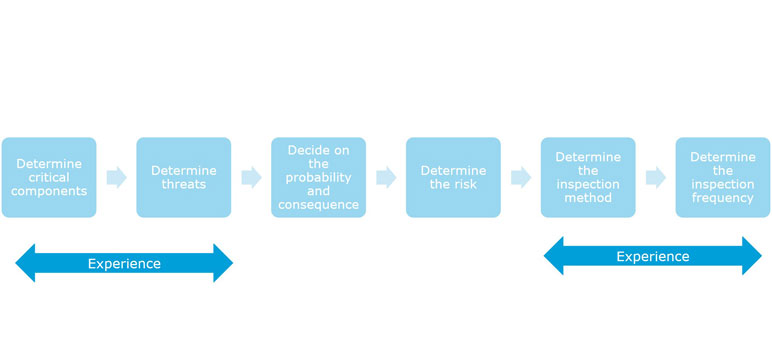

DNV’s Fixed and Floating Structures team has developed a purely qualitative approach to RBI that focuses on the skill and judgement of the engineer and the experience of the operator. The purpose of this is to let both parties decide what is to be inspected, rather than allow a series of arbitrary ranked factors to dictate decisions. The methodology will instead guide them through a decision-making process that draws on their knowledge and expertise, in a clear and consistent fashion.

Determining the ‘quality’ of a qualitative RBI approach

A purely qualitative RBI approach has one simple goal: to allow engineers to make informed and holistic decisions based on expertise and knowledge to ascertain what presents the greatest risk, and how often it should be inspected to prevent failure (Figure 2).

Figure 2. The RBI is the combination of an assessment of the likelihood (probability) of failure with an assessment of the consequences of such failure.

Determining risk on any structure, especially offshore, is complex, given the inherently hazardous nature of the industry. Therefore, the natural response is to assume the worst and prepare for the worst-case scenario.

If money and time was no object in the oil and gas sector, inspection would become a constant and extremely costly process. However, this wouldn’t allow for common sense judgement to delineate what were credible or implausible risks through damage, deterioration or degradation, for instance. It is important to remember that with RBI, decisions made must be reassessed at incremental periods.

A fully qualitative methodology is of use when:

- No quantitative data is available and there is no methodology to process that data.

- No black boxes – they tend to obscure decision-making and relieve the engineer from the responsibility of the decision.

- Experience matters.

- There is a light touch framework for decision-making.

Once the threat is known - this is both a function of the consequence and the probability of it occurring - then the frequency to carry out a review or inspection of the whole or part of a component, can be determined. For example, fatigue on structural steel caused by rotating equipment has rarely been deemed a problem, so has a low probability of occurring. However, if it was to occur, it could quite quickly lead to limited structural failure but pose no threat to overall integrity. Using a low, medium and high-risk matrix, this would be a low outcome for both probability and consequence. Crane pedestal fatigue, on the other hand, would be judged as high-risk due to the cyclical loading which can lead to fatigue cracks occurring. From there, the inspection method and frequency can be decided. But what do the terms, low, medium and high actually mean?

Common language

DNV investigated the use of everyday language to put probability and consequence into context in a risk matrix and create a more ‘real world’ scenario. For instance, instead of medium, the words, ‘probably’, ‘even-chance’ and ‘likely’ could be used. Use of well-defined language allows different engineers with the same information, perhaps years apart, could give the same answer.

For this methodology, a series of benchmarks were created to support decision-making. To ensure everyone had the same understanding, more generic categories were suggested as well as specific guidance for each different element, such as caissons and secondary steel. However, it was agreed that the more complexity was built into the front end of the system, the engineer would have less freedom to make the right decision and therefore, less responsibility in that verdict. A more holistic approach to decision-making was required with a complementary framework to allow responses to be recorded and reassessed later.

While these real-world examples work well for probability, when used to describe consequences, a mental ‘base lining’ was required exploring the context in a way that probability does not. This helps the engineer avoid consequence escalation where everything has a deeply detrimental eventuality. We need to caution against this and trust in the engineer’s decision.

Why do things fail?

Mechanisms don’t just happen on their own, they must be initiated. A good example of this is corrosion. It’s the offshore environment that initiates the corrosion and that leads to structural failure. When designing a platform, a reasonable set of assumptions is made. For instance, poor maintenance, life span, the environment, accidental damage, new knowledge (codes, practices) and additional structures (hang off module, etc).

The methodology looks at these failure mechanisms to prevent structural failure and the likelihood and severity of any possible outcome. DNV has developed a simple flow chart which can be adapted depending on the structure in question. This poses a series of questions to guide and record the thought making process:

- How likely is the initiator likely to occur?

- Did we know about the mechanism when the component was designed?

- Are the original design conditions still valid?

- Are any new mitigations as effective as those they were originally designed in?

My matrix is bigger than yours

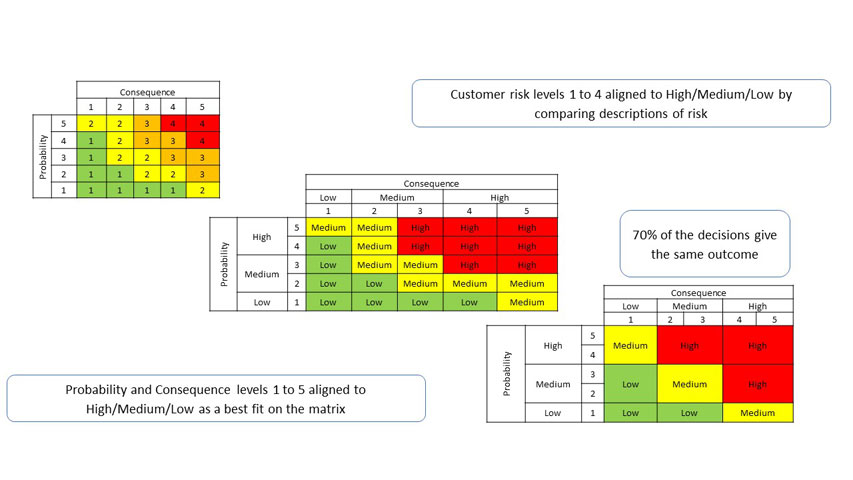

Simplicity is key to the most workable and understandable risk matrix. Choice overload can impair cognitive judgement and make decision-making a more arduous process. DNV asserts that RBI approach is kept to three levels of probability and consequence, any more than three and it is difficult to make a consistent decision – which can be swayed by varying opinions. As shown in Figure 3, this example of a 3x3 matrix ensures 70% of decisions give the same outcome while the remaining 30% gives a more conservative answer.

Figure 3. Probability levels 1-5 aligned to high/medium/low as a best fit on the matrix.

This level of accuracy doesn’t make any great deal of difference when determining an inspection frequency or method.

The Golden Rule in this methodology is that ‘The engineer is always right’ but only when armed with a light touch process to document the judgement, to ensure consistency when reassessing an issue. If the output of this system does not agree with the engineer’s experience of what the outcome should be, rather than ‘fudging’ the inputs to get the correct output, the engineer should simply state what the outcome should be and why. No system can be expected to cover all the situations that may occur. As there are no arithmetic operations involved in this process, the judgement and experience of the engineer should always outweigh the system as every structure is different.

Read the article online at: https://www.oilfieldtechnology.com/hse/19082021/qualitative-risk-based-inspection-keeping-it-simple/

You might also like

Kongsberg Maritime selected by Samsung Heavy Industries for 9-ship Shuttle Tanker project for Tsakos Group

The vessels are being constructed for Greek shipowner Tsakos Group and will be a bare-boat charter by Brazilian energy logistics company Transpetro, supporting offshore operations in Brazil’s pre-salt oil fields.