Cameron introduces new, high-availability BOP control system

Published by David Bizley,

Editor

Oilfield Technology,

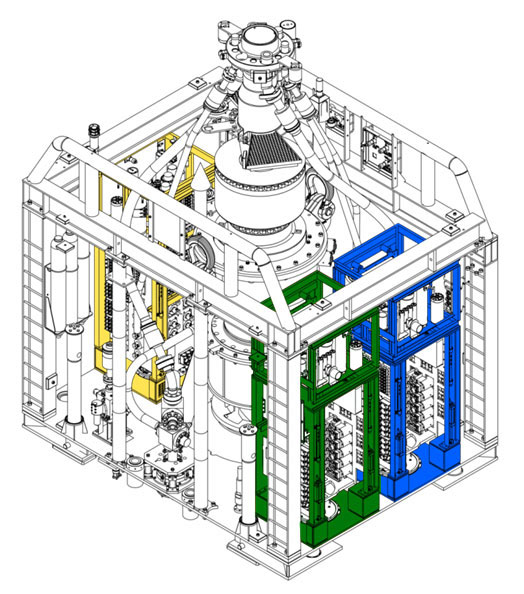

Cameron has announced the Mark IV control system featuring a redundant, three-Point of Distribution (POD) design as an option for its subsea blowout preventers.

The blowout preventer (BOP) is a primary component of the subsea drilling stack system. BOPs are very large devices that contain well bore pressures by sealing around drill pipe, and if necessary, shearing drill pipe and sealing off the well bore. The control system POD operates all functions of the subsea stack, including the BOPs, from the sea floor in water depths of up to 12 000 ft. Retrieval of the subsea control system POD for unexpected maintenance can cost drillers days of downtime and millions of dollars.

Current subsea BOP control systems use a two-POD design, which provides a redundant spare. If the primary POD becomes unavailable, drillers can switch to the second POD to control their BOPs and seal the well before bringing the BOP stack to the surface for repair of the non-working POD.

Cameron introduced the first multiplex BOP control system for subsea drilling and has developed a unique, patent pending three-POD stack design, which will provide drillers with additional operational reliability through redundancy. Adding a third POD can improve the subsea control system’s availability to as much as 98%, and reduce the likelihood of a POD-related stack pull by up to 73%.1

In addition to redundancy, the design of the POD for the new control system increases reliability through the POD design. Each POD has been designed to offer increased functionality in a smaller, lighter package. The simpler design can reduce leak paths by utilising 50% less tubing compared to Cameron’s previous two-POD design. Additionally, the number of available functions has increased 33% to accommodate newer, eight-cavity stacks. POD size was reduced 26%, and weight is one-third less than competitors’ control PODs.

David McWhorter, Vice President and General Manager of Cameron’s Drilling Systems Division, Pressure Control commented, “Customers have expressed concern that downtime caused by PODs in need of repair can cost tens of millions of dollars. Adding a third POD to our system dramatically reduces the risk of costly downtime attributed to the PODs.”

Cameron is a leading provider of flow equipment products, systems and services to worldwide oil, gas and process industries.

1. Actual availability will vary with conditions.

Adapted from a press release by David Bizley

Read the article online at: https://www.oilfieldtechnology.com/exploration/16072014/cameron_introduces_new_high_availability_bop_control_system/

You might also like

bp begins oil production from major new platform offshore Azerbaijan

bp, as operator of the Azeri-Chirag-Gunashli (ACG) project, has announced the start-up of oil production from the new Azeri Central East (ACE) platform as part of the ACG field development in the Azerbaijan sector of the Caspian Sea.