Working with wireless technology

Ali Faras, Kuwait Oil Company, Kuwait, demonstrates how wireless monitoring systems installed at wellheads improve operations, reduce field visits and improve HSE.

Kuwait Oil Company (KOC) needed to add remote monitoring systems on 357 wellheads to improve upon existing data gathering procedures. These procedures required frequent trips to each wellhead to record data, and manual data entry to get this information into production optimisation systems.At KOC, remote monitoring of wellheads is called real time surveillance, and they expect it to provide four main benefits:

To realise these benefits, the company first needed to build a foundation for analysis and optimisation, which requires access to the real time data needed to improve day-to-day asset management. This required installing instrumentation at each wellhead, and then exploiting the breadth of available technologies to monitor key process variables in real time.

Wired and wireless solutions were both considered, with wireless instruments selected due to lower costs, faster implementation, and reduced HSE risks.

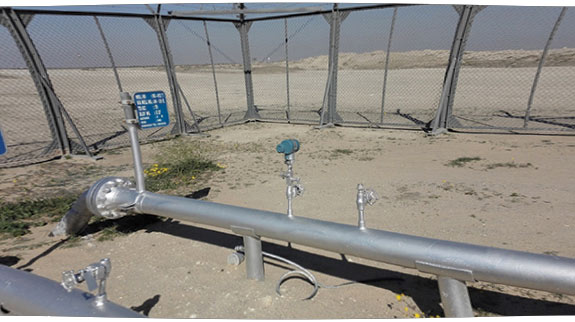

Figure 1. This lift station is similar to many others used by KOC. A wireless transmittter measures wellhead pressure, and a second wireless transmitter measures wellhead temperature. Readings from these and other devices are transmitted to and shown in the main control room.

Initial implementation of real time surveillance

For the first few decades of oil production, the company relied on the pressure in underground formations to extract oil. But by late 2010, it started depending on artificial lift stations to produce the required pressure, with the number of lift units increasing dramatically each year thereafter to the present total of 357 (Figure 1).

Manual operation and monitoring of such a high number of wells began to be very tedious and time-consuming, and it presented hazards to field personnel. Optimising production was almost impossible due to insufficient instrumentation at many sites and lags in data collection and subsequent data entry. Both of these delayed real time surveillance.

A wireless gateway and an RTU panel collect data from pressure, temperature, H2S and CH4 transmitters. The RTU also interfaces with the pump controller and the downhole gauge.

Real time automation was first introduced as a solution in early 2012. KOC started with a few wells, and used the information from these wells in very basic optimisation applications to demonstrate value. A typical wellhead with a lift station was equipped with the following instrumentation, data gathering andTank level measurement.

Although these measurements provided tremendous value, early implementations indicated the average time needed to install the necessary wired instrumentation was one to two weeks per well, much too long given the hundreds of wells requiring upgrades. There were also operational constraints with wired instrument installation including required excavation procedures and costs, and HSE risks.

These issues led KOC to consider a wireless solution as it met their two main criteria:

Measurement devices designed to work together with simple means of integration, and possessing diagnostic capability to enable data validation and analysis.

The company decided to adapt wireless technologies and preconfigured software because they felt it would increase standardisation and facilitate getting production online faster. WirelessHART instruments and related components from Emerson Process Management were selected because of KOC’s prior positive experience with other Emerson products and services, and because of the investments Emerson made to work as a partner on projects.

All the instruments at each wellhead are connected to an Emerson wireless gateway, and the gateway is connected back to the central control and monitoring room via Wi-Fi and WiMAX networks. An Emerson RTU is installed at each site to provide the required local monitoring and control, and this unit is also networked back to the central control room via the gateway.

This wireless transmitter measures flow line pressure. A change in the flow pressure can indicate a reduction in flow, leading to decreased production or wellbore damage.

Benefits of wireless monitoring

With wireless technology, instrument installation requires no signal wiring, and only some of the wireless instruments require power wiring. Each wireless instrument is connected back to the gateway through the WirelessHART mesh network. This is in contrast to a traditional wired installation, where each instrument requires power wiring, and signal wiring must be run from each instrument to an RTU gateway.

By eliminating most of the required wiring and corresponding infrastructure, installation time was reduced from one week per wellhead to two wells per day, a tenfold improvement. Installations costs were cut in half, saving US$3000 per well. HSE risks were also reduced as much less excavation and wiring work is required in these potentially hazardous areas. Data accuracy is in the range of 99.9%, more than sufficient for the application, and data availability is also high.

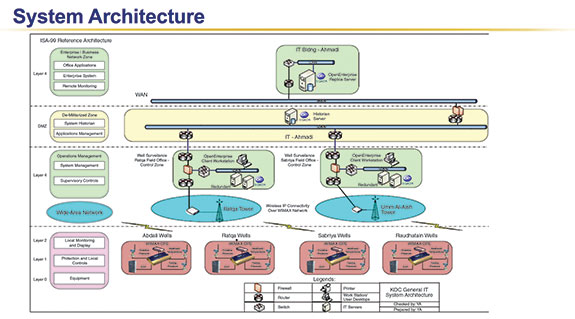

The existing SCADA system has been expanded to accommodate all of these new wireless points of measurement, with the system architecture depicted in Figure 4. SCADA data management software tools provide easy visualisation, trending and analysis – turning raw data from wireless instruments into actionable information – which the company uses to improve production planning. Now that the surveillance foundation is in place, consideration is being given to utilising diagnostic tools to confirm instrument health and data validation.

One benefit quickly realised is a reduction in troubleshooting time as technicians have remote access to a wealth of information regarding the operation of each well. This allows them to diagnose problems quickly, and to arrive at the site with all the tools needed to address any issues.

With the expansion in artificial lift units and corresponding instrumentation, the variety and real time availability of data is dramatically increasing in quantity and complexity. Finding the expertise to filter and interpret data in a timely manner is a challenge, but one well worth the effort as it promises to deliver even more benefits through optimisation of wellhead operation, and ultimately the entire oil production system. Optimisation will allow the company to fine tune well production, and maintain oil reservoir recovery to meet production targets.

Data gathered by wireless instruments at each of the 357 wellheads is used by the SCADA and other systems to optimise production, reduce downtime and improve safety.

Conclusion

Enhancing oil production by installing a monitoring system has many challenges, including start-up delays, excavation, costs and HSE risks. Wireless instrumentation allowed KOC to meet these challenges and implement an automation strategy based on real time surveillance, analysis and optimisation. This achievement has lowered operating and maintenance costs, improved HSE performance, and increased production.

A wireless mesh network infrastructure is now in place at each wellhead, making installation of additional WirelessHART instruments a quick and inexpensive proposition should the need arise to install additional points of measurement.

How the technology works

WirelessHART is a self-organising mesh technology in which field devices form robust wireless networks to dynamically mitigate obstacles in the process environment. Other wireless technologies employ similar strategies, with varying degrees of effectiveness.

WirelessHART and other wireless technologies do not require communication wiring and related infrastructure. Some wireless devices require power wiring, but the vast majority of deployments use battery power and thus operate completely without wires. Wireless networks communicate data back to host systems securely and reliably, and can be applied to both control and monitoring applications.

An installation of the technology requires, first of all, a wireless instrument transmitting data according to the IEC 62591 WirelessHART standard. If a transmitter does not have WirelessHART, a wireless adapter can be installed on most any existing two or four-wire device.

With WirelessHART, each wireless device transmits to a gateway managing a specific wireless field network. Typically, the gateway is assigned to a process unit. Each gateway will manage its own wireless field network, and can have an assigned HART Tag like any HART device. Each wireless field network in a plant has a unique Network ID to prevent devices from attempting to join the wrong network.

WirelessHART devices can communicate through each other to send messages to the gateway, forming a self-organising ‘mesh.’ The mesh extends the range of a device beyond that of its own radio. For example, a wireless device may be several hundred feet away from the gateway with obstacles between, but power-efficient ‘hops’ through neighbouring devices closer to the gateway ensure a reliable, extended range.

The gateway connects to the control and monitoring system via a wired or wireless high-speed link, typically Ethernet.

Where is wireless used?

The chief advantage of wireless systems are that they can be installed virtually anywhere in an efficient, timely and cost-effective manner. Battery-powered transmitters require no wired infrastructure or local power supply, so they can be installed in locations far away from a process unit’s wired fieldbus and power wiring. They can also be installed in locations where supplying power and cabling would be too expensive or hazardous. This flexibility means that there are benefits from using wireless in both greenfield capital projects and existing brownfield facilities.

Greenfield capital projects are typically looking to make 10 to 20% of traditionally wired signals wireless. EPC contractors and plant owners see strategic incorporation of wireless as beneficial in terms of reduction in physical fixed infrastructure. They also see wireless technology as a means to manage schedule risk and cost escalation/containment, and as a solution for reducing space requirements and weight.

Wireless can reduce schedule and cost impacts because there is always the potential for scope creep and additional I/O as projects progress. The later in the project a change comes, the greater the risk of jeopardising the project schedule and budget. Wireless can usually accommodate these changes better than fields.

Quite often, additional measurements are eliminated from the design process of a new or retrofit project because those signals are deemed too costly to implement during the Capex phase of a project. If those measurements are needed later, adding wired instrumentation can be much more costly than wireless solutions.

On these types of brownfield projects, wireless solutions are a good way of supporting operational excellence programs to improve plant productivity and reliability, and compliance to emerging environmental and safety legislation.

A plant-wide wireless network can be installed with minimum disruption to fixed infrastructure such as wiring, conduits and cable trays. Adding wiring to these existing assets can be costly, and interfering with ageing assets can cause unforeseen issues such as disruption of signal transmission.

Read the article online at: https://www.oilfieldtechnology.com/drilling-and-production/26072016/working-with-wireless-technology/

You might also like

Kongsberg Maritime selected by Samsung Heavy Industries for 9-ship Shuttle Tanker project for Tsakos Group

The vessels are being constructed for Greek shipowner Tsakos Group and will be a bare-boat charter by Brazilian energy logistics company Transpetro, supporting offshore operations in Brazil’s pre-salt oil fields.