Finding the right candidate, Part 2

Published by David Bizley,

Senior Editor

Oilfield Technology,

Ken Montgomery, Niksam, Singapore, explains the importance of thorough candidate analysis when selecting new vessels for FPSO conversion.

The owners had a list of requirements for the vessel that included: cargo capacity, recent cargo oil and ballast tank condition reports, cargo pumping rates, the ability to heat cargo to 60 °C (ambient ~ 30 °C), Cap 2 (Hull), power available and last dry-dock within 18 months. A desktop exercise compiled by owners illustrated that on the surface all three vessels met the basic criteria they required.

At the time of the inspections by surveyors the three vessels were in service and cargo tank entry was not possible, meaning the decision on which vessel to purchase would be based on ‘cargo tanks sight unseen’. One vessel had 3P, 3S, for’d and aft peak ballast tanks available for inspection, two vessels had for’d and aft peak tanks available. All three vessels had a fairly recent UT survey done and it was noted that diminution was within acceptable limits. Class records were acceptable and none had any conditions or serious remarks.

The prices for each of the vessels were fairly close and none had a significant advantage over the others.

The owners and investors rejected vessel C, as the hull paint coatings, deck pipework and fittings were not in as good a condition as on vessels A and B, and were prepared to make an offer to purchase either A or B.

As with every owner in these situations, there was a sense of urgency to get the project started; this is not an abnormal occurrence as stakeholders can get weak stomached in a surprisingly short period of time, especially when news headlines are quick to point out any downturn in the industry. The owners and investors were cautioned that it was premature to take a decision on which vessel was the better as an insufficient amount of analysis had been done.

For 70% of its life, vessel A was mostly employed on long trans-Atlantic/Pacific runs, 15% on runs between Europe and the Arabian Gulf and 15% other runs. The cargoes carried were mainly medium to heavy API sour crude, which often required heating.

Vessel B on the other hand had been a shuttle tanker in the North Sea for about 80% of its time carrying cargoes of Brent, which is a light sweet crude having API ~38° and sulphur content of approximately 0.4%. For the remainder of its life it had been on North trans-Atlantic hauls with heated cargoes.

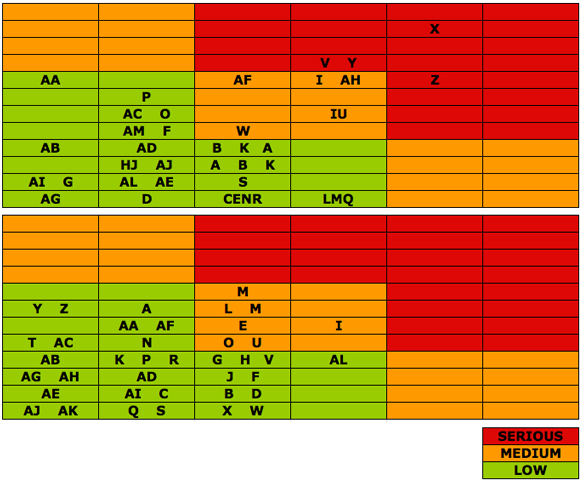

For A and B, data was gathered on the number of cargoes carried, types of cargo, heated unheated, trading areas, crew nationality, shipyards where the vessels were dry docked, information from the CAP survey and arranged it into a matrix where it was risk assessed and weighted using a sensitivity analysis program and the results of vessels A and B are illustrated in Figure 1.

Letters in the red area are serious factors having a high probability of causing owners financial loss, the orange area is medium probability, which encompasses almost all Aframax tankers at 15 years age and the green area is low probability and of no real concern.

The analysis was structured to consider fatigue cracking probability based on quantitative and qualitative inputs and, as can be seen from Figure 1, Vessel B came out as the better option for the candidate vessel despite having been working in the North Sea and North Atlantic for all of its life. Heavy weather did have an impact on vessel B and twisting, bending and racking forces were of concern.

Figure 1. Sensitivity analysis program results for vessels A (top chart) and B (bottom chart).

What let Vessel A down was the amount of heated sour cargoes carried on long ocean passages, loaded and in ballast, where the hull form endured many twisting, and bending cycles, heated and unheated in proximity to H2S. All crudes have some water in them which when mixed with H2S becomes Sulphuric acid H2SO4. Sulphuric acid has very powerful dehydrating properties and when it removes water heat is produced 4 increasing the probability of corrosion.

Vessel B was purchased, and when a close up inspection of the cargo tanks was performed, there were no surprises.

Part 3 of this article will be available soon!

Part 1 of this article can be reached here.

Adapted by David Bizley

Read the article online at: https://www.oilfieldtechnology.com/drilling-and-production/23092013/finding_the_right_candidate_part_2/

You might also like

Subsea7 awarded contract offshore Egypt

Subsea7 will be responsible for the engineering, procurement, commissioning and installation of flexible pipelines, umbilicals, and associated subsea components for a tie back to existing infrastructures.