Coiled Tubing Drilling: a specialised niche that’s growing fast

Toni Miszewski, Managing Director, AnTech looks at how the growing area of Coiled Tubing Drilling is helping operators exploit fields previously considered economically unviable.

Operators are always looking for efficient methods to access mature fields and extract the maximum yield from existing reserves. As a niche offering within the rapidly growing Coiled Tubing (CT) sector, Coiled Tubing Drilling, (CTD) provides an efficient and economical opportunity to exploit fields which were previously deemed too expensive.

Background

The first advances in CTD took place in the 1970s. These experimental operations had varying results and required generations of technical advances to make the technique effective and commercially viable.

Global advances in metallurgy made it possible to spool and unspool tubing without causing metal fatigue, and with the development of larger diameter tubing and smaller diameter of downhole motors, the possibility of CTD became a reality. Activity grew steadily starting in the early 1990s leading to tens of thousands of wells being drilled with hybrid rigs, mainly in Canada, and by the mid-90’s scores of projects across the world were adopting this approach.

Initially many CTD jobs were relatively straight forward, working on shallow wells. As the technology has developed, during recent years, the approach has been used on more complex and deeper wells, whether that be to drill entire wells, or to drill multilaterals to several targets.

As a new generation of engineers and technologists filter through the ranks, they are increasingly looking for different technologies in order to unlock the potential of wells and increase efficiency. However, there is still a lot to learn about the benefits of using the technology.

Benefits of CTD

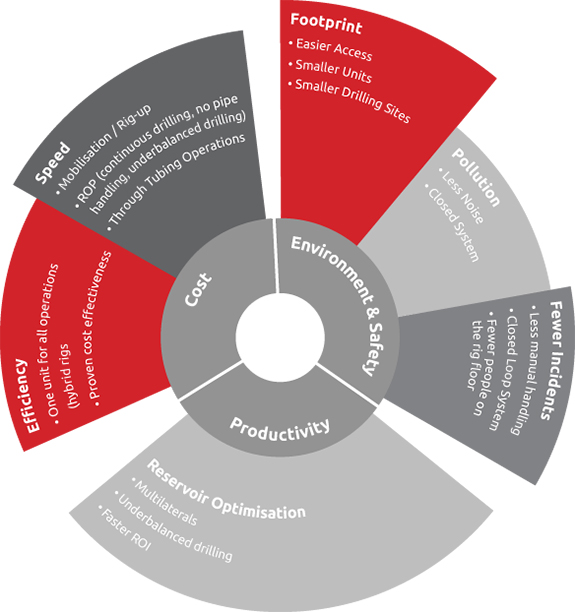

At present, the benefits of CTD can be summarised by increased speed, reduced cost, smaller footprint, more environmentally friendly, increased safety and increased productivity.

CT has a wide range of potential applications but it is in drilling that this innovative approach offers the greatest potential for efficient oilfield management. Compared to conventional rotary drilling, CTD equipment and techniques can reduce costs by 30-40%.

The main advantage of CTD is underbalanced drilling, whereby making it possible to maintain the pressure in the wellbore below that of the formation to ensure continuous drilling and pumping. This can be vital where there is low well pressure or to protect the formation and maintain the integrity of the well. It can also enable the well to continue to produce whilst drilling and usually increases the rate of penetration (ROP).

Directional Coiled Tubing Drilling (DCTD) includes the use of a bottom hole assembly (BHA) to provide directional survey, gamma, pressure and temperature logs as the drilling progresses. This enables the well’s trajectory to be adjusted and corrected in response to the measurements taken by its sensors.

Under the right circumstances it can expand the range of drilling options whilst delivering significant cost savings.

Figure 1. CTD advantages diagram.

Three primary advantages include:

- The ability to drill easily and safely with the well in an underbalanced (UBD) condition from start to finish.

- The ability to drill fast with a corresponding reduction in cost and a shortening of time to bring the well on production.

- The ability to drill a well with a low environmental footprint in terms of space, noise and well control.

A new field approach

Over the past 20 years the advantages of DCTD have resulted in significant costs savings as part of a complete field approach, and have transformed the economics and recoverability of regions such as Alaska and Saudi Arabia.

Successful DCTD operations rely on a holistic approach to project planning. Just as there are special characteristics to the drilling process, there are other well construction methods which need to be adapted to CT techniques. Added to this is the fact that most ongoing CTD operations take advantage of the ability to conveniently drill underbalanced which brings in the spectre of deploying and retrieving the drilling and other BHA’s under pressure.

A whole combination of elements are required in order to complete a successful DCTD operation. Planning, modelling, whipstock setting, milling, deployment and real time data monitoring all play a part in these complex operations.

DCTD is a specialised niche in the oil and gas market with significant potential. Successful use of DCTD calls for the close collaboration of experts in a number of fields. The right combination of drilling, logging, well engineering, testing and software skills is critical to success. As technology improves, and the environmental benefits are recognised, the range and number of drilling operations looks set to increase.

Written by Toni Miszewski, Managing Director, AnTech. Edited for web by Cecilia Rehn.

Read the article online at: https://www.oilfieldtechnology.com/drilling-and-production/03092014/coiled-tubing-drilling-is-growing-fast-and-helping-operators-exploit-expensive-fields/

You might also like

Kongsberg Maritime selected by Samsung Heavy Industries for 9-ship Shuttle Tanker project for Tsakos Group

The vessels are being constructed for Greek shipowner Tsakos Group and will be a bare-boat charter by Brazilian energy logistics company Transpetro, supporting offshore operations in Brazil’s pre-salt oil fields.