The Application of Non-Triazine H2S Scavenger in Bubble Towers for Natural Gas Applications

Published by Leah Jones,

Digital Administrator

Oilfield Technology,

In this paper, Vink Chemicals GmbH assess a new non-triazine H2S scavenger technology for natural gas applications using contact/bubble tower treatment. Hydrogen sulfide (H2S) poses a number of issues for oil operators both at a HSE and commercial level. Across the entire natural gas supply chain from exploration to refineries, it is essential to remove H2S. There are a number of methods employed to remove H2S the main being the use of a bubble tower where the gas comes into contact with a liquid H2S scavenger.

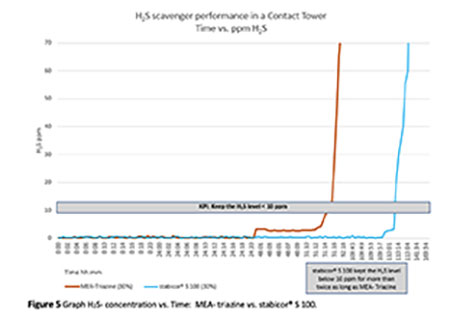

Monoethanolamine triazine (hexahydro-1,3,5-tris(hydroxyethyl)-s-triazine) also known as MEA triazine or HHT, is the most widely used H2S scavenger in these gas applications. However, its use is fraught with several issues including overdosing and fouling that severely impacts operations. 3,3'-methylenebis 5-methyloxazolidine (stabicor® S100), known industrially as MBO, presents an alternative solution to traditional scavengers in natural gas bubble tower applications. It offers the same benefits as triazine but outperforms it by increasing the consumption of weight H2S/weight of scavenger and reducing the polymeric by-product deposition. It is produced in large commercially available quantities. It is 99% active so product, transportation, freight, and storage costs are significantly reduced. It can also be readily diluted with numerous types of solvents before use. The following experimental detail describes the comparative performance of stabicor® S100 and MEA triazine in a contact tower simulation for H2S breakthrough evaluation. stabicor® S 100 showed excellent performance and was able to maintain the H2S level below 10 ppmv for around 110 hours. In contrast, the industry standard H2S scavenger MEA-Triazine kept the level below 10 ppmv only for around 51 hours.

Under field conditions this translates into the need to exchange the not fully consumed scavenger solution resulting in a significant waste of resources. The formation of solids has been observed with all scavenger products. Experience has shown that the formation of solids with stabicor® products can be significantly reduced by using polar solvents such as alcohols or glycols. Feedback from the field has shown that solids formed by stabicor® S 100 products have different, more beneficial physical properties, resulting in easier and less costly maintenance and cleaning. Overall, the higher scavenging chemical capacity of stabicor® S 100 allows longer residence times in the contact tower and consequently longer exchange intervals can be achieved. A case study is presented that shows improved H2S- mitigation of 3 gas fields in North America with stabicor® S 100 over MEA triazine.

Read the article online at: https://www.oilfieldtechnology.com/special-reports/10072023/the-application-of-non-triazine-h2s-scavenger-in-bubble-towers-for-natural-gas-applications/

You might also like

tengizchevroil starts WPMP operations at tengiz oil field in Kazakhstan

Chevron has announced today that its 50 % owned affiliate Tengizchevroil LLP (TCO) has safely commenced operations at its wellhead pressure management project (WPMP) at the Tengiz oil field in Kazakhstan.