Baker Hughes awarded first technology agreement with Petrobras to develop definitive solution for pipeline corrosion

Published by Elizabeth Corner,

Senior Editor

Oilfield Technology,

Baker Hughes announced on Tuesday a joint technology development programme with Petrobras to provide a definitive solution for stress corrosion cracking due to CO2 (SCC-CO2) in flexible pipe systems.

The pre-commercial agreement encompasses development and testing, as well as a purchase option of the resulting next-generation flexible pipes, which will have an extended service life of 30 years in high-CO2 environments. The collaborative effort between Baker Hughes and Petrobras will be primarily executed at Baker Hughes’ Rio de Janeiro Energy Technology Innovation Centre and nearby flexible pipe systems manufacturing plant.

“Baker Hughes has led the way in addressing SCC-CO2, and we will bring that expertise and experience to bear in developing the definitive solution to this critical industry challenge,” said Amerino Gatti, Executive Vice President, Oilfield Services and Equipment at Baker Hughes. “By deploying flexible pipe systems that last for decades, Petrobras can more efficiently unlock the vital natural resources that power the region, while also safely returning CO2 deep underground.”

SCC-CO2 was identified in 2016 and can affect flexible pipes in pre-salt fields, which have high concentrations of naturally occurring CO2. If water penetrates a pipe’s annulus area, the resulting corrosion to steel reinforcement layers can weaken structural integrity and reduce the system’s lifespan. This issue is particularly acute in Brazil’s pre-salt fields, where Petrobras is reinjecting CO2 from their production operations into wells to reduce flaring and enhance oil recovery. Petrobras has committed to limiting atmospheric emissions, and carbon capture, utilisation and storage (CCUS) is an important tool for achieving this goal.

Until now, operators in high-CO2 environments have relied on solutions that mitigate the impact of SCC-CO2 while limiting the service life of risers and flowlines. Baker Hughes flexible pipe systems and advanced monitoring technologies have proven effective at minimising this impact, and the company is a major supplier of flexible pipe systems to Petrobras.

Baker Hughes has been deeply involved in the development of Brazil’s offshore oil and gas fields for decades, and its localisation strategy contributes to the nation’s economy while strengthening its energy supply chain.

Image: Baker Hughes’ Houston headquarters (courtesy of Baker Hughes).

Read the latest issue of Oilfield Technology magazine for upstream news, project stories, industry insight and technical articles.

Oilfield Technology’s January/February 2025 issue

The January/February 2025 issue of Oilfield Technology includes keynote articles on enhancing offshore safety and risk management; technical articles on digital technology, drilling, EOR, and flow control. We also cover predictive maintenance, and production monitoring.

Read the article online at: https://www.oilfieldtechnology.com/offshore-and-subsea/20032025/baker-hughes-awarded-first-technology-agreement-with-petrobras-to-develop-definitive-solution-for-pipeline-corrosion/

You might also like

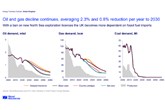

Wood Mackenzie: UK Energy Transition Outlook shows 12-point gap on 2030 climate target despite £1.5 - 2.1 trillion investment pathway to 2060

Nearly all 2030 targets now unattainable despite historic coal phaseout; offshore wind deployment trails by 20% as government races to address grid bottlenecks and spiralling costs.