Fly-ash based proppants reduce fracking costs

Energy technology company, LWP Technologies Limited has updated its shareholders on test results and R&D initiatives of its fly-ash based proppants which are used in hydraulic fracturing of unconventional oil and gas wells.

Oil and gas companies and service companies, particularly those in the United States, continue to assess technologies and products that show promise to make hydraulic fracturing more cost-effective. The effect of the current low price oil and gas environment is that producers are increasingly focused on extracting oil and gas from shallow wells where they can use cheap mined frack sand proppants, in preference to the deeper wells, which require more expensive ceramic proppants.

LWP is fortunate in that its technology can be adjusted to serve both the low cost market segment requiring lower compressive strength, as well as the high compressive strength segment.

As reported to shareholders on 11 April 2016, LWP has been focused on lowering the manufacturing costs of its ceramic proppants, so that licensees might gain a competitive advantage by delivering a superior ceramic proppant than cheap mined frack sand in areas where transportation and logistics costs are high. LWP anticipates a comparative increase in well performance over mined frack sand due to (i) higher compressive strength with less fines (ii) lighter weight, and (iii) comparable sphericity and roundness. Further, with the significantly lower specific gravity, LWP expects well costs could be markedly reduced.

Testing results of proppants made from Australian Flyash

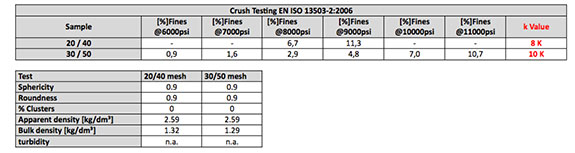

LWP has reported key test results undertaken by independent US expert testing lab GEL on the company’s proppants, using Australian fly-ash. These results continue to validate LWP’s technology and the competitive cost advantages of its fly-ash based proppants. The complete report is attached for shareholders to review. The highlights include:

Results of other testing

In LWP’s ongoing efforts to drive manufacturing costs even lower, LWP has been testing other materials combined with fly-ash to evaluate the effect on compressive strength and weight. The R&D team is very encouraged by the initial internal test results, which are set out below and demonstrate:

Chairman Siegfried Konig said:

“LWP’s R&D team continues to assess a range of processes and materials to deliver proppants that are much lower in cost and we are delighted with the independent test results of our low cost ceramic proppant. Based on these initial results, the financial modelling indicates that manufacturing costs will be approximately 50% of the cost of producing our higher strength ceramic proppants.

We are encouraged by the growing interest in our technology as oil and gas companies and contractors continue to assess ways to make hydraulic fracturing more cost-effective. While recent improvements in oil and gas prices are encouraging, LWP is well aware of the changing market dynamics in the energy sector.”

Read the article online at: https://www.oilfieldtechnology.com/hydraulic-fracturing/08062016/fly-ash-based-proppants-reduce-fracking-costs/

You might also like

DNV launches Industrial Services to support rapidly expanding energy and infrastructure markets

Evolving its inspection business into a dedicated global provider of quality assurance and inspection services for energy, infrastructure and complex industrial supply chains.