D-010: The story of the world’s well integrity standard

Published by David Bizley,

Editor

Oilfield Technology,

Norway’s NORSOK-D010 standard on well integrity was well respected before the 2010 Macondo blowout in the Gulf of Mexico, but the disaster prompted a wide-ranging review in order to absorb the lessons learned and further advance safety. Terje Løkke-Sørensen, well engineering manager at Add Energy, led the group of 16 experts who compiled the fourth revision and here he describes how it came about, what’s new about it, and why he believes D-010 is becoming a de facto international standard.

Ever felt frustration when you’re traveling and your phone charger won’t fit the socket? It prompts us to ask, how can something so basic not be the same in all countries? Isn’t it merely a matter of agreeing to make the change and setting the time? And if an electrical socket can’t be standardised internationally, what hope is there for something as complex as an oil and gas well?

Not much, you might think. But the latest revision of Norway’s NORSOK-D010 standard on well integrity gathered so much international feedback and is generating so much interest around the world that I believe a common, sensible approach is now closer than ever.

But first, a bit of background.

In 1993 the oil industry in Norway developed an initiative called NORSOK with the aim to increase Norway’s competitiveness in delivering field solutions. Out of this initiative a number of standards were developed to make deliveries and operations more cost efficient through standardisation, under the stewardship of OLF (now Norsk Olje og Gass).

This was also driven by the fact that the NPD (now PSA) had changed their regulations in 1992 from being prescriptive, as in, “you must survey the borehole every 100 m”, to being more functional and outcome-based, as in “you should know where the borehole is at all times”. It gave operators more leeway to establish their own specifications, and at the same time less room to hide in the ‘letter of the law’. The D-010 Drilling and Well operations standard, with its focus on how to conduct operations and what type of equipment should be used, arose out of this approach. The requirements were a mixture of functional and prescriptive, and focused primarily on drilling, completion and abandonment activities.

The NPD regulators were smart – they made selective parts of international standards (ACME, API) and the NORSOK standards as recommended ways of complying with the regulations: “ … in order to comply with the regulations, the 5.1.2 in NORSKOK D-010 should be used.” Operators did not have to follow D-010 but, if they didn’t, the burden of proof fell on them to demonstrate that their own approach fulfilled the requirements. It gave the industry both the responsibility to justify their methods in fine detail, and a way of doing it. It also made it more difficult for the industry to complain about regulations being out of date.

The 2000s: D-010 becomes the well integrity standard

In 2003 revision number three of D-010 (Rev. 3) was released. In this revision D-010 was significantly changed and expanded to focus on well integrity in planning and execution of all drilling and operations throughout the lifecycle of the well. Over 50% of the previous revision was removed, while a lot of new material was added – a total of 167 pages. The phrase ‘well integrity’ was defined and got its own listing in Wikipedia. The revision was undertaken by experts from operating companies both Norwegian and international, and the new D-010 was unique in addressing well integrity in all conventional types of operations: drilling, testing, completion, wireline/coiled tubing/snubbing, as well as including underbalanced drilling, production and pumping operations, before terminating the well by plugging and abandonment.

Also unique about the new D-010 was its extensive use of well barrier schematics (WBS) to illustrate the well barriers to put in place for a specific operation. Norsk Hydro had been using this technique since the release of the 1992 drilling regulations, stating that well barriers should be defined, accepted and monitored. Norsk Hydro generously made their WBS library available to the editors of Rev. 3, resulting in the inclusion of many drawings. To supplement the WBS, a library of 50 detailed descriptions of well barrier elements – the essential building blocks of an effective well barrier – were developed.

Figure 1. An illustration of a WBS.

The illustration in Figure 1 is a WBS – the blue line shows the (primary) well barrier that prevents inflow of formation fluids (oil/gas/water) into the wellbore. If any element of this should fail, the red line shows the elements in the secondary barrier. In an ideal world these barriers should be completely independent – in the case below they are not as they share the casing (element no. 2).

Rev. 3 quickly gained recognition among operators and regulators in Norway. It was regarded as a very useful basis on which operators could develop their own approach to well integrity and it intensified industry focus on well integrity as both goal and discipline. It helped that it was freely available on Standard Norge’s website, like the rest of the NORSOK standards. It also gained international recognition as global firms ‘exported’ it to other regions, there being no comparable standards anywhere else.

Macondo triggers a new revision

The Macondo blow-out in the Gulf of Mexico in 2010 challenged authorities in various jurisdictions and the industry at large to examine regulations and practices to see what more could be done to prevent large accidents. Many reports were published worldwide, amongst them was Norsk Olje og Gass’s 2011 Macondo lessons-learned report, which contained some very specific and useful recommendations for updating the D-010 standard.

Again, with wide voluntary support of the industry a task force was established and work on Rev. 4 began later in 2011. More than 2,300 submissions from 35 companies were received and processed.

The new revision was finally published in June 2013. Rev. 4 provides more information, particularly regarding plugging and abandonment. It includes managed pressure drilling, which was not included in Rev. 3. It has more on relief well plans and requirements for capping equipment. It identifies nine additional well barrier elements to provide a fuller complement of barrier management building blocks.

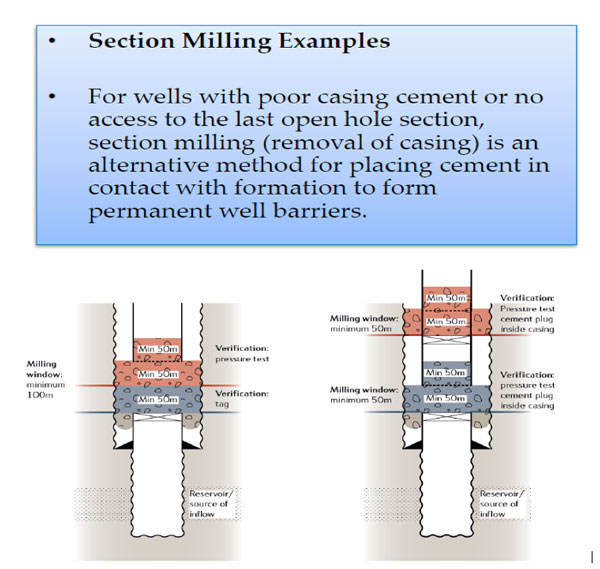

For example, Figure 2 below shows how permanent well barrier cement could be put in place by the removal of poorly cemented casing by section milling.

Figure 2. An illustration of how permanent well barrier cement can be put in place through the use of section milling.

Reaction to Rev. 4 has been muted so far, which I believe it can be explained partially by the fact that the regulations in Norway still refer to Rev. 3, and partially by the fact that the latest revision resulted from extensive consultation with industry and captures current best practice, meaning there are few surprises.

However, operators should be ready because Rev. 4 does include more robust safety enhancements that will require greater thoroughness and will likely drive costs up. For instance, there is the requirement that you should be able to kill a well by drilling one relief well, not two or three, which will have an impact on well design.

For those of us involved in drafting the revision it is gratifying to see how Norsok-D010 is becoming something of an international standard. Major operators like Shell and BP engaged with the consultation process, offering feedback from their global organisations. We also had comments from many countries around the world. Australia is particularly keen to use Norsok-D010. A colleague and I recently gave a two-day course on the standard there, which was attended by multiple operators.

I was asked recently if I think D-010 is a world-leading standard for well integrity and, while I am biased, it’s true to say that I have not found any other standard that covers so much as D-010. Others around the world tend to cover only parts of a well’s lifecycle, whereas D-010 covers the whole lifecycle.

It’s designed to be easy to use and straight to the point. For instance, I use it as a checklist to scrutinise clients’ drilling schedules, and I see a lot of operators in Norway take sections of text straight out D-010 to incorporate into their management systems. I can also see situations where personnel on the rig fall under time pressure from shore to get the job done and here the standard supports them in insisting on no shortcuts, which is essential for well integrity.

One may reflect on why it took close to two years to produce Rev. 4, but that discussion best reserved for another time.

A wise man said:

“A standard is worth nothing – unless it is referred to.”

This is especially true for NORSOK D-010.

Terje Løkke-Sørensen will be giving an in- depth presentation about NORSOK D-010 Well Integrity Standards Rev. 4 and its use for problem solving in the planning and execution of well activities at the 2nd Annual Well Integrity & Abandonment Conference, June 3-4, 2014. More than 200 senior well integrity and abandonment executives will be gathering at the Aberdeen Ardoe House Hotel for the largest meeting of its kind. For a detailed technical program and expert speakers list, visit www.decomworld.com/wi

Adapted for web by David Bizley

Read the article online at: https://www.oilfieldtechnology.com/exploration/10032014/the_story_of_the_worlds_well_integrity_standard/

You might also like

Rystad Energy shares oil market update

Rystad Energy shares oil market update