Strainstall supplies load pins for Shell FPSO project

Shell Stone offshore project

Strainstall UK Limited has been selected to work with SBM Offshore on the Shell Stone project, an ultra-deep oil and gas development in the Gulf of Mexico. The project is currently the deepest production facility in the world, at a depth of approximately 2900 m.

FPSO unit

The project involves the use of an FPSO (Floating Production Storage and Offloading) unit, which has a forward mounted turret with a disconnectable buoy (Buoyant Turret Mooring or BTM) allowing it to weathervane in normal conditions and disconnect from the FPSO in the event of a hurricane.

Unique BTM design

The unique BTM design required six specially designed load pins to measure the forces between the buoy and the FPSO, as they are an essential component of the detachable buoy system, and a critical element to ensure the safety of the FPSO and BTM. A custom design was required to meet SBM’s requirements and to incorporate the unique features; Strainstall was selected to design and manufacture such a loadpin.

Strainstall experience

In addition to the design, manufacture and testing of the load pin a comprehensive documentation package was specified by SBM. This was provided by Strainstall, who has years of experience in providing specific packages for a variety of industries including offshore oil and gas, marine, industrial, aerospace and nuclear.

Unusual shape

Due to the challenging technical requirements of the pin, Strainstall was contracted to produce an unusual shaped design, which was ATEX and IECEx certified with internal amplifiers to monitor the clamping forces between the vessel and the detachable buoy.

Adapted from press release by Katie Woodward

Read the article online at: https://www.oilfieldtechnology.com/exploration/09042014/strainstall_load_pins_for_fpso_project_131/

You might also like

Petrobras increases Proved Reserves in 2025

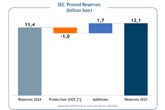

Petrobras discloses its proved reserves of oil, condensate and natural gas, according to SEC (US Securities and Exchange Commission) regulation, estimated at 12.1 billion boe, as of December 31, 2025.