Expro case-study

Published by Joseph Green,

Editor

Oilfield Technology,

Objectives

An operator of a deepwater well in the Gulf of Mexico experienced a work string failure while milling cement.

Initial thoughts were that they had jumped a box in the work string but attempts to re-stab into the pin were unsuccessful and when the work string was pulled and it was discovered that it had twisted off above the pin leaving fragments in the hole, which were eventual retrieved.

Expro were approached as the operator wanted to confirm the integrity and sealing surfaces of the wellhead/tubing spool and decided a downhole camera should be used for evaluation.

Expro Well Intervention

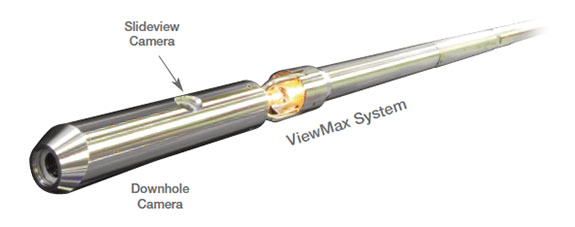

Expro’s ViewMax camera system was mobilised and run in the well.

Flexible solution – can operate on conventional electric line.

The camera inspection revealed two large fragments of the work string lodged in the wellhead (figure one) and as a result special clean-out BHAs and brushes were run to remove the debris.

Camera deployed for a second time to verify the outcome of the brushing operation.

Value to client

Saved valuable rig time using Expro’s ViewMax camera on electric line to inspect the wellhead.

Despite having the debris in the wellhead, using the camera to verify the debris had not moved after thorough brushing gave the operator confidence to proceed knowing it was securely lodged and would not fall down later incurring further costly operations.

Client’s confidence also factored into their decision not to pull the tubing spool to retrieve the debris, which would have added approximately US$10 million to the well completion.

Adapted from press release by Joseph Green

Read the article online at: https://www.oilfieldtechnology.com/drilling-and-production/08052015/expro-viewmax-camera-gom-wellhead-923/

You might also like

Rhino Resources and Halliburton to sign contract for integrated deep-water services offshore Namibia

Halliburton Company has announced it has been awarded a deep water integrated multi-well construction contract by Rhino Resources, a private company engaged in both onshore and offshore energy exploration in Africa.